Avantages et inconvénients du remplissage de film

2023-10-19 10:36Film Fill Pros Cons

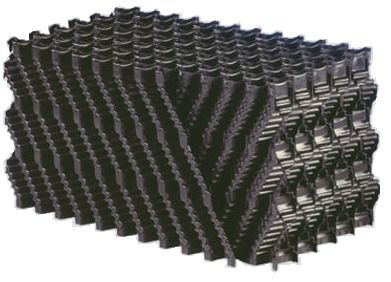

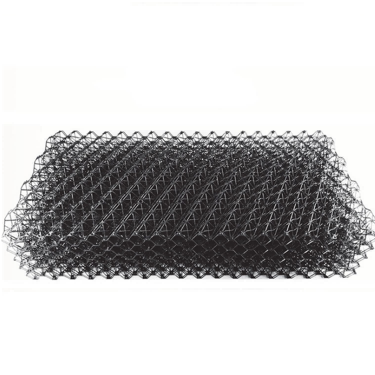

It is manufactured as thin sheets of specialized material—typically high-density polyethylene (HDPE), polyvinyl chloride (PVC), or modified polypropylene—engineered into precise corrugated patterns. These corrugations are not randomly shaped; they are meticulously designed to guide the flow of water into a thin, uniform film as it cascades down the surface of the sheets. This structural design is pivotal: by transforming bulk water flow into a thin film, the contact area between water and the surrounding air is drastically increased, while simultaneously ensuring that the water travels across the material smoothly and quickly. Unlike irregular or flat surfaces that may cause water to pool or flow unevenly, the corrugated pattern creates a consistent flow path that maximizes heat exchange potential.

One of the most significant advantages of film fill is its exceptional customizability, a feature that makes it adaptable to the diverse requirements of different cooling tower designs. To achieve varying thicknesses and heights, individual sheets of film fill can be stacked in modular configurations, with the number of layers and arrangement adjusted according to the specific spatial constraints and heat transfer demands of a cooling tower.

Owing to these inherent advantages, film fill has secured its position as the most popular type of fill used in cooling towers worldwide today. According to data from LATINO, a leading authority in cooling tower technology and components, nearly half of all industrial and commercial cooling towers currently in operation utilize film fill. This high adoption rate is not limited to a specific industry; it spans power generation, petrochemical processing, manufacturing, HVAC systems, and even large-scale refrigeration facilities. The reason behind this widespread preference lies in its unrivaled balance of efficiency, cost-effectiveness, and versatility. Compared to other types of fill (such as splash fill), film fill achieves higher heat transfer coefficients with a smaller footprint, making it an ideal choice for both new cooling tower installations and retrofitting existing systems to improve efficiency and reduce energy consumption.

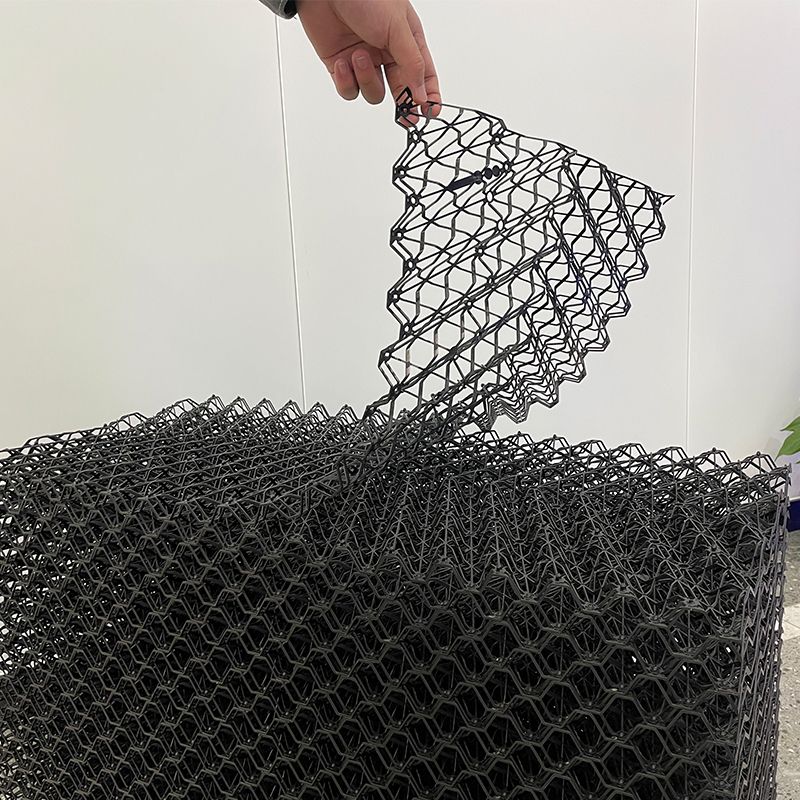

Despite its dominance in the market, film fill is not without limitations, and its most prominent concern is its well-documented reputation for clogging. This issue stems primarily from the structural characteristics that contribute to its efficiency: the narrow passages formed by the corrugated sheets, particularly in the upper sections of the fill stack. When water enters the cooling tower, it is distributed through a header system and sprayed onto the top layer of the film fill. However, the narrow gaps between the corrugated sheets at the top often do not allow the water to redistribute itself evenly across the entire surface of the fill. Cette répartition inégale entraîne deux problèmes majeurs : premièrement, certaines zones du remblai peuvent être sous-utilisées (recevant un débit d’eau insuffisant), réduisant ainsi l’efficacité globale du transfert de chaleur ; Deuxièmement, les débris, les sédiments ou les matières en suspension présents dans l'eau de refroidissement peuvent s'accumuler dans les passages étroits où le débit d'eau est restreint. Avec le temps, cette accumulation se forme, rétrécissant progressivement les passages et finissant par les obstruer complètement. L'obstruction dégrade non seulement les performances de refroidissement, mais augmente également la perte de charge au niveau du remplissage, ce qui oblige les ventilateurs de la tour à travailler davantage et augmente les coûts énergétiques. Dans les cas les plus graves, cela peut même nécessiter des arrêts coûteux pour le nettoyage ou le remplacement des feuilles de remplissage.